Project 2: Reverse Engineering - Object Dissection & Modeling

I am really glad for the object I chose. It was fun to really examine it with my digital calipers and stare deep into the ergonomic and compact design that was clearly thought out by the manufacturers of it. It made me appreciate what, I imagine, a whole team of people pour research into designing.

That appreciation started pretty early, with the basic curvature of the main handle. It also functions as the compartment that holds all of the different chisel heads, so it had to be designed in a way that was comfortable to hold for as many people as possible, strong enough for people to press into constantly for hours at a time, while still being light-weight and hollow.

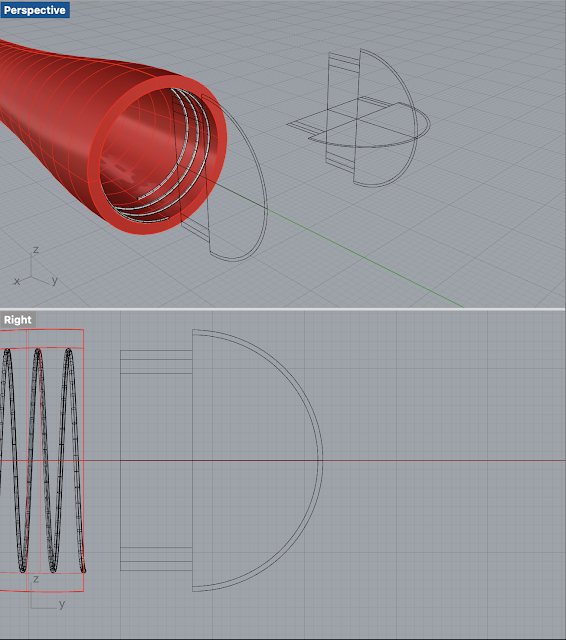

I used various key measurements to map out the curvature as best I could, and then used the curved lines as my rails for a sweep2 command. For most of my modelling I used this same basic idea of creating a wire frame cross-section and using sweep.

While I don't think I have it quite perfect yet, another part that I found really enjoyable was trying to match the matte finish of the red plastic. It's a fine line getting it to look realistic, and I think I managed to portray the soft/smooth surface fairly well.

Once I got into some of the smaller bits I realized just how precise the measurements really had to be for this to be a functional tool. It's the difference of half-millimeters and quarter-millimeters but it changes whether or not the carving heads actually sit snug in the device or not.

And if they don't, then that would be a pretty miserable carving experience.

It looks pretty good laid out, but I am curious if it would actually function if I fabricated it. I think it would work in a really crude sense, but I don't think it would be as comfortable as the one I own, some of the curvatures and organic shapes on the most crucial parts were hard to directly measure and map. Especially the chisel. I think they create them as a flat piece of metal with a sort of oval shape and then fold it appropriately to how they want the chisel. I'm not sure at what stage they would sharpen it, but even that was hard to recreate as the tip goes down to a fine edge.

All in all, I think it would work, but I might leave it to the pros to make my next linoleum cutter. I'll just focus on the art with a new appreciation for their work.

Comments

Post a Comment